BLOG

The Role of Pressure Regulators in Hydraulic Systems

Controlling pressure during the operation of hydraulic systems is a key factor that directly affects the performance, lifespan, and safety of the equipment. A pressure regulator is a device that ensures the fluid pressure within the system remains within the prescribed range, regardless of changes in load or flow conditions.

At MPH, we offer a wide and high-quality selection of pressure regulating valves. These small but essential components play a vital role in the safe operation of hydraulic equipment, as their automatic function prevents the system pressure from exceeding critical levels.

Hydraulic Valve – Precise Control Inside Hydraulic Equipment

One of the most important components for the efficient operation of hydraulic systems is the hydraulic valve. These components regulate the flow, direction, pressure, and speed of hydraulic fluid, directly influencing machine performance, response time, and safety.

Whether it's industrial machinery, agricultural equipment, or mobile hydraulics, selecting and installing the right valve is essential to ensure system reliability and long service life.

At MPH, we offer various models of hydraulic check valves, each representing high quality, guaranteeing efficient operation with every part purchased from us. If you need assistance selecting the ideal component, feel free to contact our expert team for helpful advice and technical information.

The Fundamentals of Hydraulic Motor Speed Control

Hydraulic motors are widely used in both industrial and agricultural applications. Controlling the speed of a hydraulic motor plays a key role in ensuring the equipment operates optimally across different use cases.

At MPH, we offer a wide selection of hydraulic motors. Our range includes various types and performance categories, so everyone can find the model that best suits their needs. Our expert team possesses in-depth knowledge of every product we sell and can provide useful advice and detailed information to assist in the selection process.

The Fundamentals of Hydraulic Systems and Their Role in Modern Engineering

Hydraulic systems transmit mechanical energy through fluid, allowing for precise and efficient force transmission. They play a crucial role in the operation of industrial machines, agricultural equipment, and construction tools, and are essential for performing precise and complex motion sequences.

Blower Compressor – The Foundation of Efficient Gas Handling

In many sectors of modern industry, there is a growing need for storing and transporting large volumes of gas. Blower compressors play a key role in the efficient handling of natural gas, hydrogen, carbon dioxide, and various other industrial gases.

These devices not only allow for optimal pressure control within storage systems, but also contribute to economic and continuous operation in gas transfer processes.

At MPH, we offer a wide and high-quality selection of blower compressors, making it easy to find the ideal product tailored to the specific demands of your application.

The Function and Role of Pressure Gauges in Hydraulic Systems

The efficiency and safety of hydraulic systems largely depend on the accurate monitoring and regulation of pressure. Pressure gauges play a key role in this process, as they allow for the continuous observation of system operating conditions.

These devices help prevent malfunctions, optimize performance, and ensure safety whether in industrial, agricultural, or residential applications.

At MPH, we offer a diverse and high-quality selection of pressure gauges, so it's easy to find the ideal model for a wide range of applications. It’s important to choose a pressure gauge compatible with the system’s operating conditions, as only then can it effectively fulfill its purpose. Our expert colleagues are available to assist in the selection process and provide valuable tips and technical guidance.

Controlling Hydraulic Motor Speed Requires Precision

Hydraulic motors are used in a wide range of industrial and agricultural applications, where precise speed control is essential to ensure optimal performance and accurate operation. Setting the correct speed not only increases productivity but also contributes to energy efficiency and extends the lifespan of components.

At MPH, we offer a wide and high-quality selection of hydraulic motors. If you want to be sure that you’re choosing the right equipment, consult our expert colleagues, who can provide valuable insights and advice.

Introduction to the World of Hydraulic Hand Pumps

Hydraulic pumps play a crucial role across a wide range of industrial, agricultural, and even residential applications, as they enable the efficient conversion and transmission of hydraulic energy. Hand pumps are particularly important in situations where access to electric or mechanical power is unavailable. They are also extremely useful in environments where simplicity, reliability, and portability are key requirements.

At MPH, we offer a wide range of hydraulic pump accessories, making it easy to find the ideal suction port or by-pass valve for any model or application.

Hydraulic Cylinder: A Cornerstone of Industrial and Agricultural Machinery Operation

Hydraulic cylinders are essential components of modern industrial and agricultural machinery, as they enable high-force output in a compact form with efficient performance. These devices perform mechanical work using hydraulic fluid pressure, making them capable of moving extremely heavy loads.

At MPH, we offer a wide selection of hydraulic cylinders, exclusively from well-known and trusted manufacturers. Choosing and applying a cylinder that is fully compatible with your machinery is crucial. Our expert staff is available to provide helpful advice and information, ensuring that you find the ideal model for your specific application.

Hydraulic Tipper Cylinder – For Efficient and Precise Lifting Operations

Hydraulic systems are of vital importance in many industrial and agricultural applications, especially in the case of tipper vehicles. These systems enable trucks, trailers, and other transport vehicles to unload their cargo efficiently and quickly. The hydraulic tipper cylinder is the central component of such systems, converting hydraulic pressure into mechanical motion, ensuring smooth and reliable lifting.

At MPH, both types of tipper cylinders are available: front-mounted and underbody cylinders can be found in our product range. We exclusively distribute components from reliable and recognized manufacturers, so you can be confident in the quality and long service life of our products.

To find the product that best suits your operating conditions, feel free to ask our expert colleagues, who can provide you with valuable advice and technical information.

Flow Control in Hydraulic Systems

One of the key elements in the efficiency and reliability of hydraulic systems is flow control. By using the right high-quality flow control valves, energy consumption can be optimized, pressure fluctuations can be prevented, and smooth operation of hydraulic cylinders can be ensured.

Maintaining precise control over hydraulic flow contributes significantly to the long service life and efficient operation of the equipment. At MPH, we offer a wide selection of industrial hydraulic valves capable of delivering effective and precise flow regulation, even in high-pressure systems and demanding industrial environments.

Reliable and Stable Connections in Hydraulic Systems – Hydraulic Quick Couplers

The presence of perfect connections is essential for the safe and efficient operation of hydraulic systems, and hydraulic quick couplers play a key role in ensuring this. These components ensure the tightness of the equipment, thereby allowing the uninterrupted flow of hydraulic oil.

The hydraulic quick couplers available at MPH are specially designed elements that enable the fast and flawless connection of hoses and lines. As a result, there is no need to worry about leakage, performance loss, or unexpected disconnection.

The Key to Highly Efficient Operation of Hydraulic Cylinders

Hydraulic systems are present in nearly every field of modern agriculture and industry from construction and mining to assembly lines. One of the fundamental components of hydraulic equipment is the hydraulic cylinder, which converts hydraulic pressure into physical motion.

At MPH, we offer a wide range of hydraulic cylinder types, allowing you to find the ideal model for various systems and applications. If you are unsure about your selection, our expert team is ready to assist you with helpful advice and detailed information.

Hydraulic Quick Couplers for Fast, Safe, and Leak-Free Connections

In hydraulic systems, reliable and leak-free connections are crucial for proper operation. Hydraulic quick couplers allow components to be connected or disconnected easily and quickly without the need for special tools or time-consuming assembly.

These components are widely used in agricultural machinery, industrial equipment, and mobile hydraulics, where frequent connection and disconnection is required.

What You Need to Know About Hydraulic Cylinders

Hydraulic cylinders are fundamental components in modern engineering and industrial automation. These devices convert hydraulic energy into mechanical motion, delivering high force output in a compact design.

Whether it’s agricultural machinery, construction equipment, or industrial automation, hydraulic cylinders are essential where precise, powerful, and reliable motion is required.

At MPH, we supply various types of hydraulic cylinders, so everyone can find the most suitable model for their specific application. If you are unsure about your selection, feel free to contact our expert team for helpful advice and detailed information.

The Role of the Hydraulic Manifold in Modern Engineering

Hydraulic manifolds are fundamental components of hydraulic systems, responsible for directing, distributing, and regulating fluid flow. These compact yet complex units ensure that a hydraulic system operates precisely as designed.

The manifold is not only essential for power transmission, but also plays a major role in the control, safety, and energy efficiency of the machinery. Since different applications have varying requirements, hydraulic manifolds are available in a wide range of configurations and functionalities.

At MPH, we offer a broad selection of pressure relief valves, which play an important role in the operation of hydraulic manifolds.

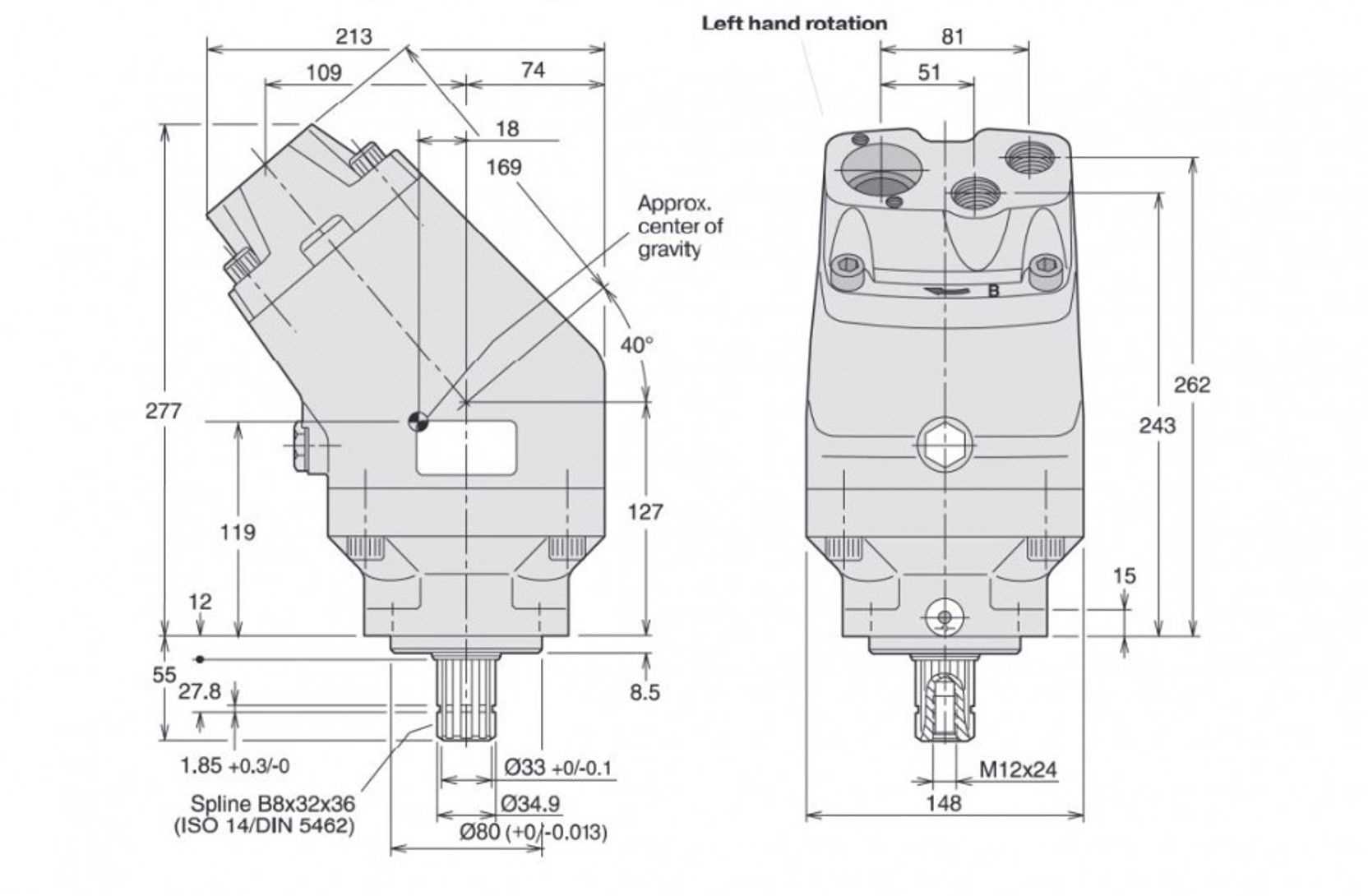

Hydraulic Pump Drive – Efficient and Reliable Power Transmission

The pump is the central component of hydraulic systems, ensuring the flow of pressurized fluid, which enables power transmission between different types of equipment. The hydraulic pump drive plays a critical role in determining the performance, efficiency, and longevity of the entire system.

At MPH, we offer a wide selection of hydraulic pumps for our customers. Our high-quality units include various types and performance levels, making it easy to find the ideal product for different applications. If a customer is unsure about which model to choose, our expert team is ready to assist with helpful advice and detailed information.

Role and Operation of the Hydraulic Tank in Hydraulic Systems

One of the essential components of hydraulic systems is the hydraulic tank, which stores hydraulic oil and plays a fundamental role in the efficient operation of the equipment. This component ensures that the required amount of fluid is always available, maintaining the appropriate level and pressure.

The smooth flow of oil is crucial for the efficient and safe operation of the system. The hydraulic tank is also important as it allows contaminants and air bubbles in the fluid to settle, ensuring a cleaner and smoother flow within the system.

In our webshop, you can find all necessary accessories for hydraulic tanks to ensure proper operation.

Role and Operation of a Hydraulic Pressure Relief Valve

Our current article focuses on the hydraulic pressure relief valve, a crucial component in hydraulic systems. It plays a fundamental role in maintaining the safe and efficient operation of the system. Its function is to prevent overpressure in the hydraulic equipment, thereby protecting components from potential damage.

At MPH, we offer a wide range of hydraulic pressure relief valves, making it easy to find the ideal product for various applications.

Operation of Gear Pumps - Everything You Need to Know

The operation of gear pumps is not widely known, yet it is one of the most common and simple types of hydraulic pumps used extensively in hydraulic systems. Its operation is based on the rotation of gears, which pump fluid through the system.

At MPH, we offer a wide range of gear pumps, making it easy to find the ideal product for your needs. We exclusively carry reliable models from well-known manufacturers, ensuring dependable performance and long lifespan. If you have any questions, feel free to consult our expert staff, who can provide valuable advice and information.

Structure and Advantages of a Double-Acting Hydraulic Cylinder

A double-acting hydraulic cylinder is a device capable of executing bidirectional movement using hydraulic pressure. In this component, hydraulic fluid applies force to both sides of the piston, allowing precise control of the cylinder’s movement in both directions.

At MPH, we exclusively offer products from reliable manufacturers committed to high quality, including all types of hydraulic cylinders we carry. Our team has years of experience and is well-versed in the latest equipment on the market, ready to assist you with advice or additional information if needed.

What Does Hydraulic Cylinder Repair Involve?

Hydraulic cylinder repair is no minor task, as it involves a component used in hydraulic systems to generate mechanical force through fluid pressure.

These cylinders are widely used in construction, agriculture, automotive manufacturing, mining, and mobile hydraulics. Working with hydraulic equipment offers numerous advantages, making this form of power transmission popular.

At MPH, we offer a wide selection of hydraulic cylinders, so you can easily find the model that suits your needs. Let’s take a look at what to do if a repair is needed!

Operation and Role of Semi-Trailer Dump Trucks in Agriculture and Various Industries

Semi-trailer dump trucks play a crucial role in agriculture, construction, and other industries. They enable the transport and dumping of large quantities of bulk materials with exceptional efficiency.

These structures combine the maneuverability of semi-trucks with the high load capacity of tipping trailers, providing an effective solution for modern logistical challenges.

The dump cylinders available at MPH are of exceptionally high quality, efficiently enabling vertical movement of the trailer bed over the long term. If you have any questions about our products, our team, with years of experience and up-to-date knowledge, is ready to assist you.

Steps for Connecting a Hydraulic Control Block

Connecting a hydraulic control block requires extremely precise work. It is essential that each component connects correctly to ensure the efficient operation of the equipment and the free, leak-free flow of hydraulic fluid.

The pressure relief valves available at MPH contribute to the safe operation of the system, making their proper use crucial during assembly.

Steps for Hydraulic Hose Repair

Repairing hydraulic hoses requires specialized tools and expertise, as hydraulic equipment operates under high pressure, and any failure in the system can lead to serious issues. If the repair is not approached with caution, it may create a hazardous situation.

Hydraulic hoses available at MPH are reliable and durable products; however, continuous intensive use means they will eventually wear out. It is essential to regularly monitor the condition of the hydraulic system and replace components promptly.

Hydraulic Cylinder Manufacturing: Precision and Innovation in Modern Industry

Hydraulic cylinder manufacturing plays a crucial role in modern industry, as these devices are widely used. Applications include construction, agriculture, machinery, automotive manufacturing, mining, and numerous other sectors.

The primary function of the hydraulic cylinder is to control movement and transmit force within hydraulic systems. Their precise and correct operation is essential for efficient and safe work, which requires perfection in the manufacturing process.

The hydraulic cylinders available at MPH are high-quality, certified products from reliable manufacturers. Our goal is to provide comprehensive service in the field of hydraulic systems for our customers. Our experienced and knowledgeable team is ready to assist with useful advice and information.

Steps of Hydraulic Motor Refurbishment

Hydraulic motor refurbishment is a specialized process requiring considerable expertise and the right tools and parts. The goal is to restore a hydraulic motor that is less efficient or even non-functional back to its original condition.

During refurbishment, the equipment is dismantled into small parts. This allows for precise identification of parts that need replacement and enables thorough cleaning.

All hydraulic motors available at MPH come from reliable manufacturers, well-established leaders in their field. However, even with top quality and meticulous care, hydraulic systems have a defined lifespan. After this, individual parts may need replacement, or the system can be given new life through a refurbishment process.

Tipping Cylinder: Operating Principle and Applications

Tipping cylinders are hydraulic cylinders that use the pressure generated by the hydraulic system to lift or lower a load. Available in various sizes and capacities, they are highly versatile for different application needs.

At MPH, we offer a wide selection of tipping cylinders. Our goal is to provide our customers with quality products from reliable manufacturers, along with helpful, expert advice.

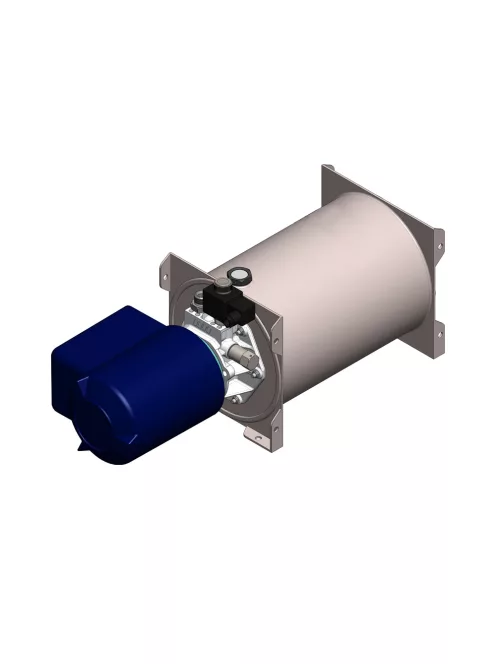

Fundamentals of Creating an Efficient Hydraulic Power Unit

Today, hydraulic systems are highly popular due to their reliability in performing tasks. To ensure that equipment operates with maximum efficiency and has the longest possible lifespan, careful consideration is essential when designing the hydraulic power unit.

At MPH, we exclusively offer models from manufacturers known for their reliable, high-quality products. By choosing our hydraulic powerpacks, you can avoid unexpected malfunctions and costly extra expenses.

Operation and Types of Hydraulic Cylinders

The hydraulic cylinder is one of the most essential components in hydraulic equipment, performing mechanical work by converting the pressure of hydraulic fluid into motion. Their applications are extensive, and they are used across various industries due to their advantageous properties.

Types and Working Principle of Gear Pumps

The operation of gear pumps is based on the principle of positive displacement. There are various types, with the most common being the traditional external gear pump, although the internal gear pump is also becoming increasingly popular.

These types of pumps are ideal for transporting and dispensing clean, high-viscosity fluids.

At MPH, we always prioritize customer satisfaction, which is why we offer only high-quality, reliable products. Our experienced team is available to assist with any questions. In our webshop, MPH offers a wide selection of hydraulic pumps, allowing you to choose the one that best suits your needs.

The Function and Applications of Directional Control Valves

Directional control valves are responsible for determining the direction of flow and starting or stopping the pressure medium. The operational functions and the number of useful ports of a particular product can often be inferred from its designation.

The simplest directional control valve is the 2/2 valve, which either disconnects the connection between the pressure line and the working point or, in the opposite position, establishes the link between the two units, with two ports. Directional control valves are widely used in both hydraulic and pneumatic systems.

Avoiding Malfunctions in Hydraulic Systems: Oil Level Checks

Hydraulic systems are complex and intricate devices, where routine procedures like checking the oil level play a crucial role. To achieve the highest efficiency and ensure the hydraulic system operates for as long as possible without malfunction, optimal conditions must be maintained.

The Selection Process and Pump Sizing

Pump sizing and, prior to that, selection can often be a time-consuming and challenging process. It’s essential to proceed with particular care, as unsuitable components can increase assembly time, and in some cases, may not meet the required specifications.

By visiting our webshop, you’ll find that MPH hydraulic pumps offer products that meet all your expectations. If you’re uncertain about pump sizing, feel free to consult our expert team. With 30 years of experience and the latest technological knowledge, our colleagues are here to assist you.

Characteristics of Hydraulic Systems

In the modern world, speed, efficiency, and high quality are naturally expected in production and other work processes. Modern technology can assist in achieving this, for example, through hydraulic systems.

At MPH, we work to ensure that you can choose from the most modern, high-quality components available. We offer a wide range of parts for hydraulic systems in both our online store and physical location, backed by decades of experience to help you select the right product.

The Role and Types of Hydraulic Hoses in Hydraulic Equipment

The hydraulic hose or pipe is responsible for transporting fluid within the system. Selecting the right material, size, and quality is crucial for these products. Proper integration into the system also requires selecting suitable fitting components. Without this, the equipment will not operate efficiently, and, in the worst case, its lifespan may be significantly shortened.

At MPH, you’ll surely find the right hydraulic hose, conveniently selected from our webshop. We also offer custom hose manufacturing to meet specific needs, even within the same day of the order.

Hydraulic Pump for Maximum Efficiency

Hydraulic pumps are essential components of mobile work machinery. The hydraulic systems of these machines are becoming increasingly efficient and capable of delivering higher performance, while it is also important to keep economic operation in mind.

Traditional fixed-displacement gear pumps no longer meet modern expectations, which is why variable displacement devices are needed. Among such products, only piston pumps are suitable for use in mobile work machinery, where it may be necessary to ensure pressures of up to 400-450 bar.

If you are looking for a piston hydraulic pump, visit our website where you can choose from a wide range of our high-quality products.