Hydraulic Pump Drive – Efficient and Reliable Power Transmission

Hydraulic Pump Drive – Efficient and Reliable Power Transmission

The pump is the central component of hydraulic systems, ensuring the flow of pressurized fluid, which enables power transmission between different types of equipment. The hydraulic pump drive plays a critical role in determining the performance, efficiency, and longevity of the entire system.

At MPH, we offer a wide selection of hydraulic pumps for our customers. Our high-quality units include various types and performance levels, making it easy to find the ideal product for different applications. If a customer is unsure about which model to choose, our expert team is ready to assist with helpful advice and detailed information.

Different Types of Hydraulic Pump Drives: Electric Drive

One of the most common drive methods is the electric motor drive, which is especially popular in industrial settings. This type is precisely controllable, easily integrated into automated systems, and provides an excellent solution for both constant and variable load applications.

The electric motor powers the pump either directly or via gear reduction, ensuring a constant rotational speed, which determines the flow rate of the pumped hydraulic fluid.

Modern motors regulated by frequency inverters enable energy-efficient operation, as the output can be precisely adjusted to the current demand. This not only supports energy savings but also reduces mechanical strain, which positively affects the lifespan of the hydraulic system.

A key advantage of the electric drive is its compact design and ease of installation. However, in environments without a reliable electrical supply, its usage can be limited.

Internal Combustion Engine Drive – The Most Common for Mobile Applications

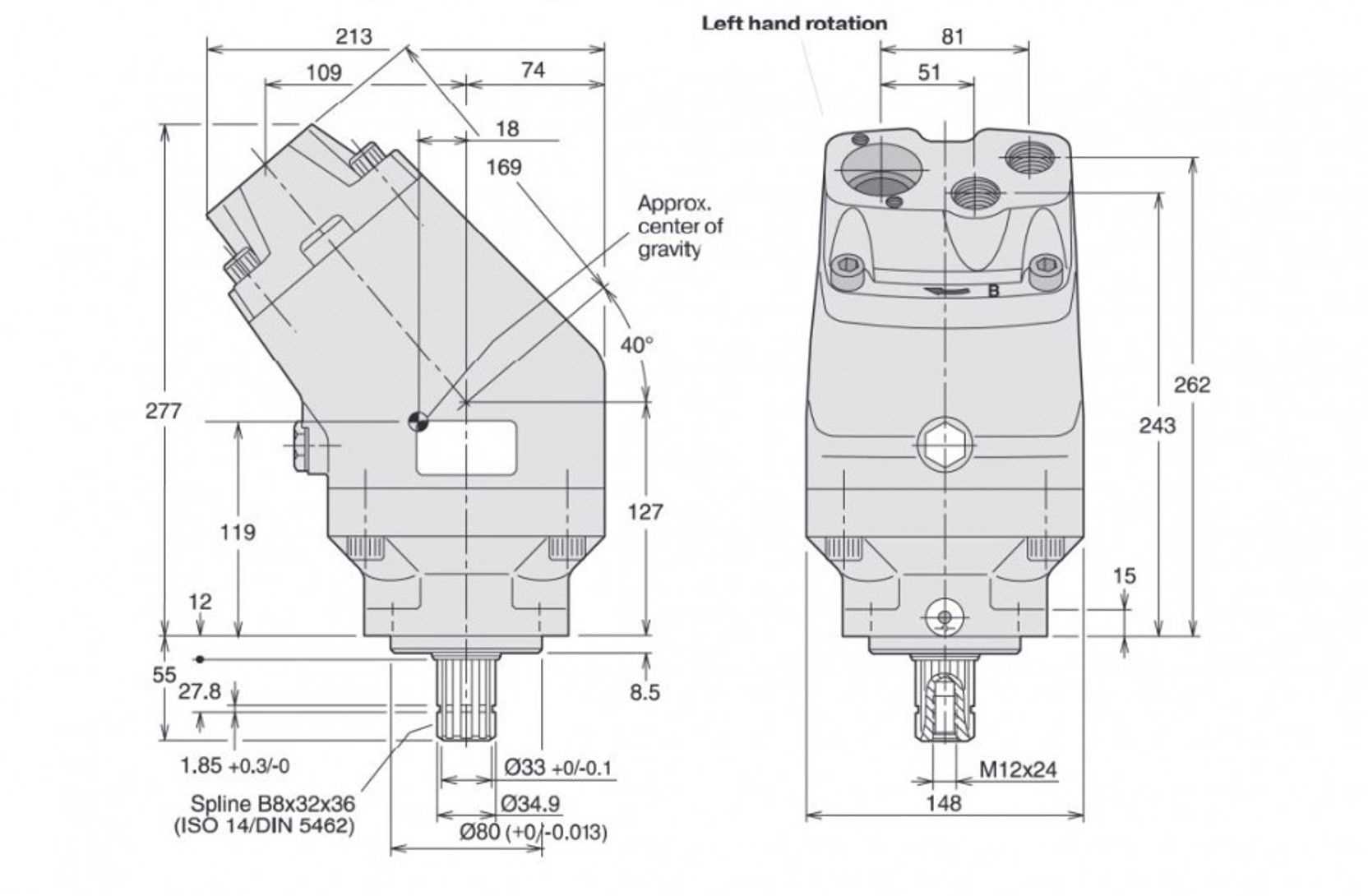

In mobile machinery, internal combustion engine drives are frequently used, as there is no need for a built-in electrical network, allowing the hydraulic system to operate anywhere. The Parker F1-051-R hydraulic pump, for example, is an ideal choice for mobile hydraulic applications due to its compact design. In such cases, hydraulic pump drives are typically powered by internal combustion engines.

The major advantage of this drive type lies in its independent power source.

Hydraulic Pump Drive: A Flexible Solution for Complex Applications

In some rare cases, systems use hydraulic motor-driven pumps. In such setups, an existing hydraulic circuit powers a hydraulic motor, which converts energy into mechanical motion to drive another pump. This solution is particularly useful when operating systems with different parameters simultaneously.

The benefits of hydraulic motor drive include compact design, easy installation, and seamless integration into existing systems.

However, disadvantages include more complex control and higher energy loss due to multiple conversions within the hydraulic medium.

There are various technologies available for driving hydraulic pumps, and the appropriate solution should be selected based on the specific operating environment and intended application.

If you have any further questions about hydraulic pump drives or the products available at MPH, feel free to contact us through any of our communication channels.